Crafted specifically for precision, the 15 ml centrifuge tubes is additionally improved by digital and mechanical enhancements. Intelligent balancing systems automatically eliminate unbalanced loads, improving performance as well as safety. Materials such as reinforced polymers and high-grade aluminum are becoming standard in rotor production, reducing wear and maximizing life in operation. Real-time sensors of temperature and speed offer feedback for reliable results. These developments not only improve separation efficiency but also allow for the achievement of stringent laboratory standards. With increasing research needs, 15 ml centrifuge tubes technology develops further to ensure better reliability and reproducibility.

The use of 15 ml centrifuge tubes traverses a number of scientific disciplines. In the manufacture of pharmaceuticals, it cleanses chemical compounds and removes residual unwanted matter. Biochemists employ 15 ml centrifuge tubes in fractionating cells and isolating organelles for subsequent studies. Drink producers utilize it to filter fluids and stabilize their products. The oil and gas industries utilize 15 ml centrifuge tubes to enhance fuel refining and clean products. {Keywords} can also be utilized in environmental analysis, aiding in the detection of pollutants in water and air samples. They are highly accurate and flexible, thus being a fundamental tool within laboratories and the manufacturing industry.

Sustainability, connectivity, and accuracy will be the areas of future evolution of 15 ml centrifuge tubes. Instruments will be made with sustainable materials and energy-efficient drives to minimize their carbon footprint. Real-time monitoring of data through cloud-based systems will facilitate real-time troubleshooting and process optimization. Portable versions will enhance accessibility in remote- or field-based studies. In pharma and biotech, 15 ml centrifuge tubes will ramp up production with intelligent automation. As technology continues to evolve, 15 ml centrifuge tubes will remain at the center of scientific innovation, bridging the gap between mechanical performance and digital intelligence.

Accurate maintenance ensures that 15 ml centrifuge tubes functions properly and safely in the long term. Regular cleaning after use prevents creation of residues that affect rotation balance. Users should inspect rotors from time to time for signs of wear and have them replaced once such signs are noticed. Calibration and balancing checks should be on a predetermined schedule. All seals and gaskets should remain in place to prevent leakage during use. Storage of equipment is to be in a stable, dry location. Proper maintenance not only preserves function but also safeguards the accuracy of every experimental result.

Used in many applications, a 15 ml centrifuge tubes uses rotational motion to facilitate material separation. Working through centrifugal force, it accelerates sedimentation, allowing scientists to sort particles based on density. Used extensively in laboratories, production plants, and environmental testing, the 15 ml centrifuge tubes simplifies processes that would otherwise be tedious. Flexible, it can be used in anything from clinical diagnostics to food and drinks. With continuing improvement in rotor design and balance technology, 15 ml centrifuge tubes today offer improved stability, endurance, and accuracy of data than before.

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

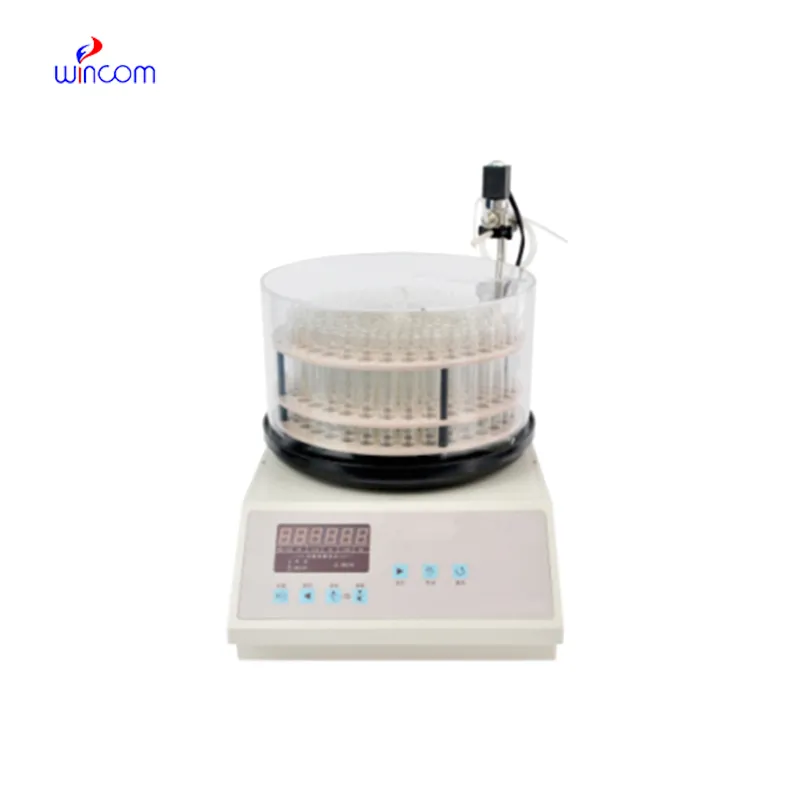

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China