Crafted specifically for precision, the centrifuge balancer is additionally improved by digital and mechanical enhancements. Intelligent balancing systems automatically eliminate unbalanced loads, improving performance as well as safety. Materials such as reinforced polymers and high-grade aluminum are becoming standard in rotor production, reducing wear and maximizing life in operation. Real-time sensors of temperature and speed offer feedback for reliable results. These developments not only improve separation efficiency but also allow for the achievement of stringent laboratory standards. With increasing research needs, centrifuge balancer technology develops further to ensure better reliability and reproducibility.

The diversity of centrifuge balancer applications shows its diversity to modern technology. Aerospace engineers utilize it to check the material properties under intense centrifugal stress. Nanotechnology utilizes it to segregate particles at micro and nanolevel for analysis and manufacturing purposes. Hospitals rely on centrifuge balancer for testing, ensuring accurate plasma and serum analysis. Food processing industries utilize it to ensure product purity and uniformity. Additionally, educational laboratories employ centrifuge balancer in teaching and experimentation, whereby students learn fundamental physics, chemistry, and biology concepts through hands-on demonstration.

{Keywords} in the future will evolve into fully networked instruments in smart laboratories. They will "communicate" with other analytical instruments through built-in digital platforms, making experimental workflows easier. Equipped with self-diagnostic systems, maintenance needs will be identified before any issues arise. Future centrifuge balancer models will emphasize energy efficiency and portability without compromising on speed or accuracy, while integration with robotics, AI-driven optimization, and user-friendly interfaces will redefine operations standards. In production and research environments, centrifuge balancer will play a key role in achieving higher productivity and sustainable performance.

Maintenance procedure routines protect the performance and safety of centrifuge balancer. The rotor needs to be visually inspected before each operation for cracks or corrosion. Mild detergents are needed for cleaning, followed by thorough drying to prevent rust. Calibration verification and vibration monitoring assist in keeping it accurate. The instrument should be set on a level surface to reduce stress on bearings. During storage, centrifuge balancer must be kept covered and not plugged to keep electronics safe. Under operator discipline and regular maintenance, laboratories can offer years of trouble-free performance.

The centrifuge balancer is an essential instrument in science and engineering. It is able to separate material constituents based on their differences in density by rotating them at very high speeds. In biotechnology, it is used to purify cells, DNA, and enzymes. In chemistry, it purifies liquids and removes impurities from them. centrifuge balancer also play a crucial role in medical diagnosis when preparing blood samples. Their mechanical precision and regulation of speed ensure safe use. Constantly enhanced design and electronic monitoring system development enhances efficiency, and centrifuge balancer are thus inevitable in numerous modern applications.

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

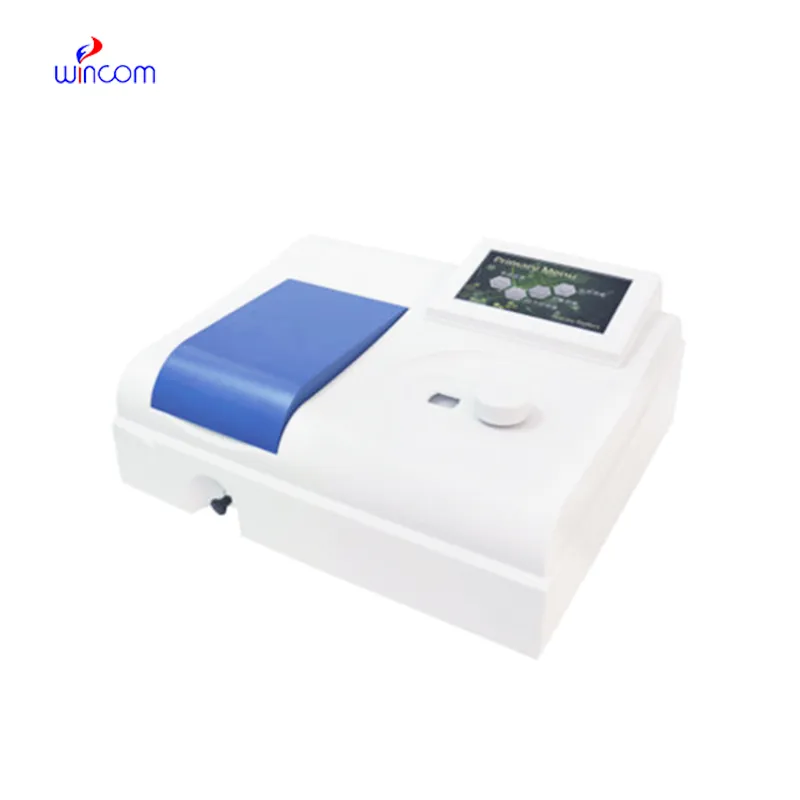

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’m looking to purchase several microscopes for a research lab. Please let me know the price list ...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China