Crafted specifically for precision, the ir-6 centrifuges is additionally improved by digital and mechanical enhancements. Intelligent balancing systems automatically eliminate unbalanced loads, improving performance as well as safety. Materials such as reinforced polymers and high-grade aluminum are becoming standard in rotor production, reducing wear and maximizing life in operation. Real-time sensors of temperature and speed offer feedback for reliable results. These developments not only improve separation efficiency but also allow for the achievement of stringent laboratory standards. With increasing research needs, ir-6 centrifuges technology develops further to ensure better reliability and reproducibility.

Clinical laboratory environments utilize ir-6 centrifuges as an important tool for proper diagnosis. Blood banks utilize it to efficiently isolate red cells, plasma, and platelets. Research laboratories employ ir-6 centrifuges to examine tissue samples for cellular and molecular studies. In the energy industry, it assists in the manufacture of biofuels by isolating the biomass components. Food scientists employ ir-6 centrifuges to reclaim fats and purify proteins while preparing products. The numerous applications reflect its capacity to enhance data reliability, process control, and yield output in a wide variety of industries and research applications.

The ir-6 centrifuges technology future lies in automation, digital control, and green engineering integration. Future models will include AI algorithms for speed, balance, and separation efficiency automatic optimization. Energy-efficient motors and recycled materials will reduce environmental impact, following international sustainability goals. Cloud connectivity will allow for remote monitoring and predictive maintenance, with less downtime. In laboratories, ir-6 centrifuges will be completely compatible with smart data systems for real-time reporting and process validation. These innovations promise greater accuracy, reliability, and versatility for research and industrial use.

Proper care routines prolong the life of ir-6 centrifuges significantly. Operators should inspect the rotor for corrosion or scratches after each use and clean with non-abrasive substances. The lid and chamber should be free from residue to prevent contaminations. Frequent lubrication of mechanical interfaces ensures effortless movement. Temperature and humidity control in the storage room protect internal parts against damage. A maintenance record helps track service time and early wear detection. Ongoing maintenance of these factors allows ir-6 centrifuges to perform reliably for decades.

The ir-6 centrifuges is an essential instrument in science and engineering. It is able to separate material constituents based on their differences in density by rotating them at very high speeds. In biotechnology, it is used to purify cells, DNA, and enzymes. In chemistry, it purifies liquids and removes impurities from them. ir-6 centrifuges also play a crucial role in medical diagnosis when preparing blood samples. Their mechanical precision and regulation of speed ensure safe use. Constantly enhanced design and electronic monitoring system development enhances efficiency, and ir-6 centrifuges are thus inevitable in numerous modern applications.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

The hospital bed is well-designed and very practical. Patients find it comfortable, and nurses appreciate how simple it is to operate.

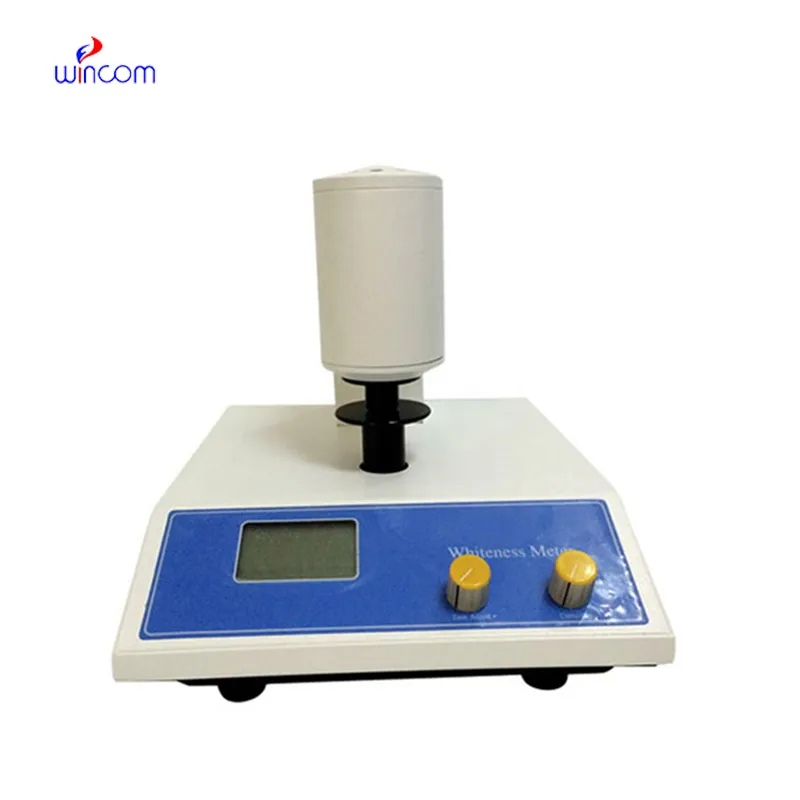

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

We’re interested in your delivery bed for our maternity department. Please send detailed specifica...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China